A unique retrofit clamp-on flowmeter device for oil and gas field optimization

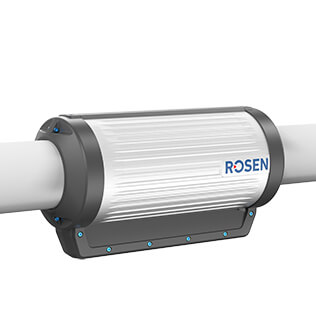

ROSEN EMAT Flowmeter

- The first multiphase flowmeter as a clamp-on device

- Easy and quick installation

- Real-time continuous well monitoring

- Remote data access

The ROSEN EMAT Flowmeter is your cost-effective solution to optimize the production of your reservoir. Simply clamped onto the well piping, it facilitates continuous real-time oil, gas and water flow measurements from each well across your oil and gas field. Exact monitoring is the prerequisite for successful data-driven production optimization and reservoir management. Therefore, the ROSEN EMAT Flowmeter significantly increases efficiency while permitting a reduction in emissions.

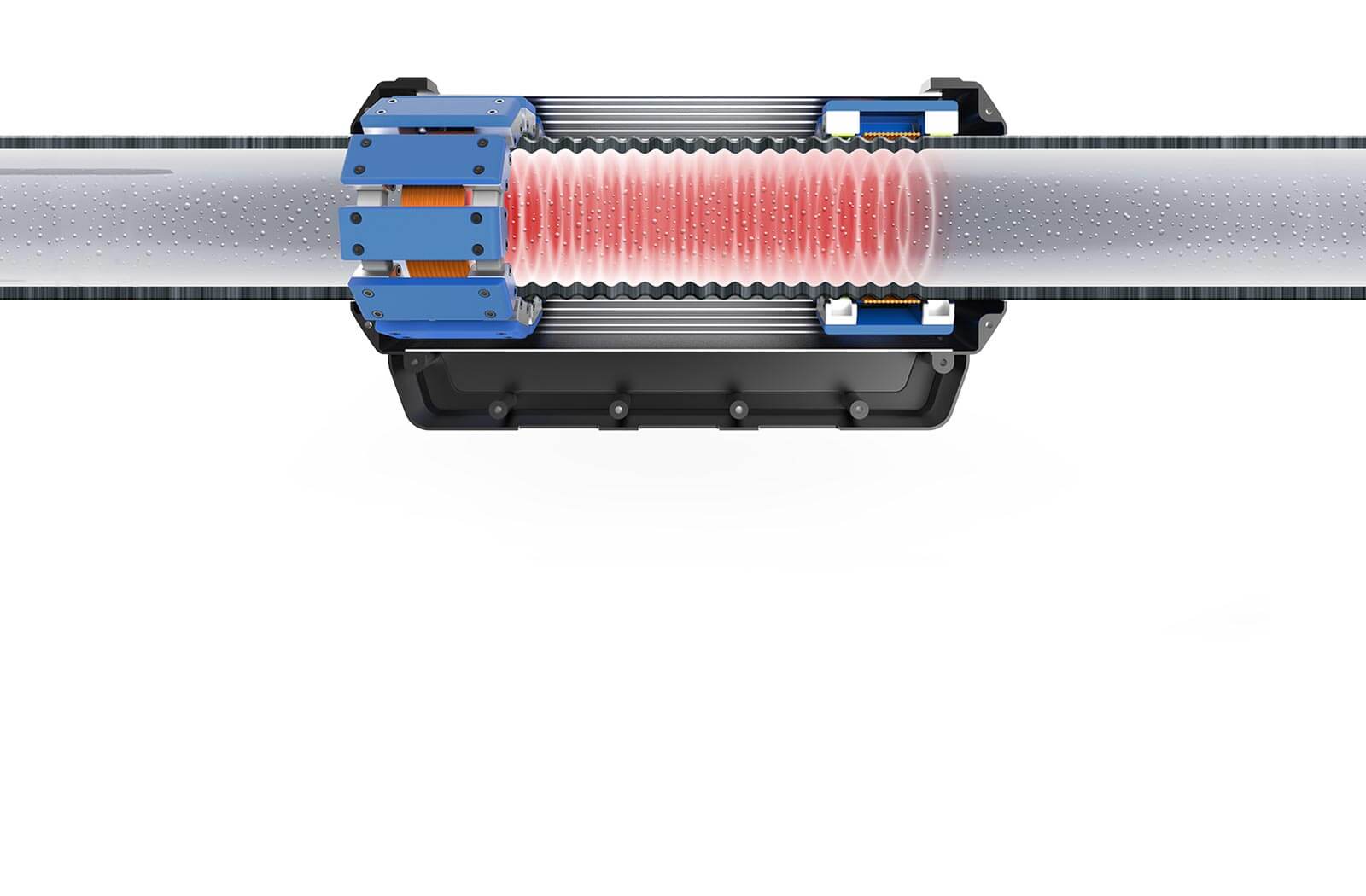

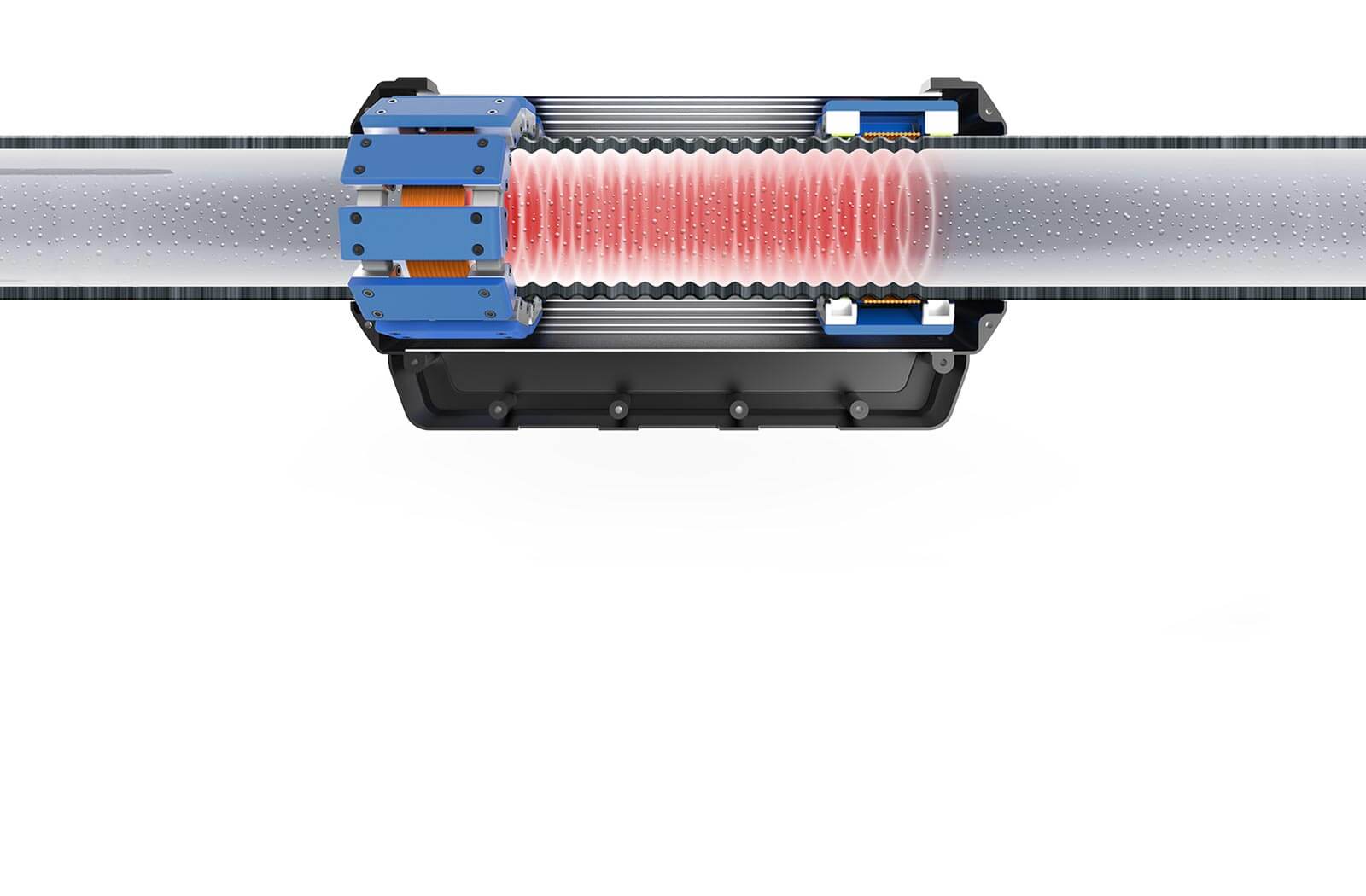

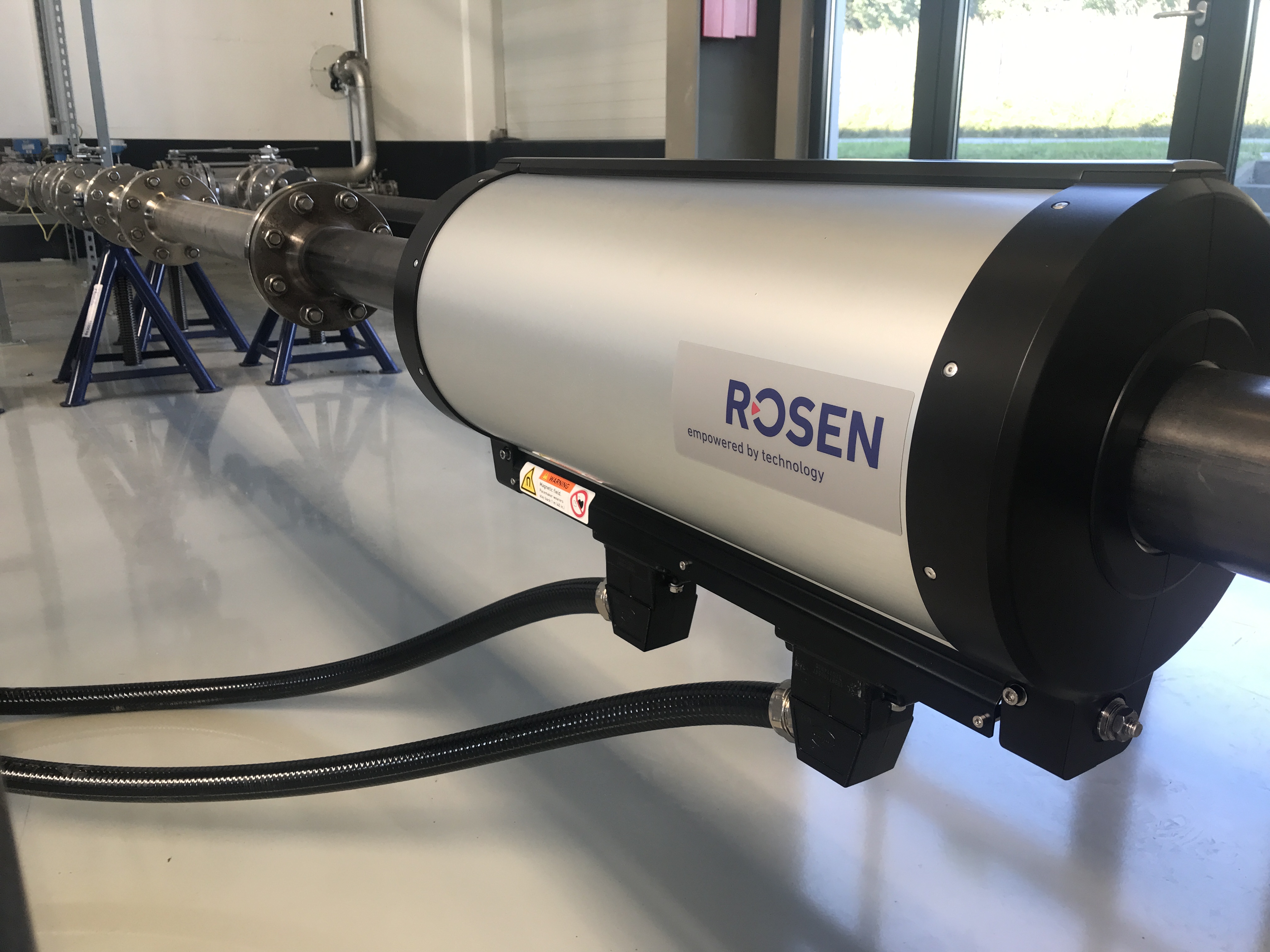

Our flowmeter comes as a non-intrusive, retrofittable device. It is easy and quick to install – no need for process interruptions or pipe preparations. Its operating principle is based on our well-proven EMAT technology, which we have refined to create flowmeters for multiphase, gas, steam and liquids applications.

ROSEN has a long history of using of Electromagnetic Acoustic Transducers (EMAT) for the inspection of oil and gas pipelines.

We use broadband ultrasonic waves to insonify an entire pipe. This enables highly accurate and stable flow measurements even under difficult conditions and in the face of disturbances for an extremely wide range of applications.

Remote data access and cloud-based data analytics enables intelligent automation and decision support. Your digitalized assets allows increasing production, decreased asset lifetime-costs and minimized on-site personnel.

Our retrofittable (clamp-on) multiphase flowmeter can be installed directly at each well-head for real-time production rate measurement. This allows for significant oil field production optimization and reliable reservoir monitoring.

The ROSEN EMAT Flowmeter: Your cost-effective solution for a high number of wells.

Flow measurement applications:

• Three-phase flow: oil, water and gas

• Two-phase flow: liquid and gas

• Watercut, flow and fraction

• Horizontal slug flow

• Wet gas

Our multiphase flow loop is situated at the ROSEN Technology & Research Center in Lingen, Germany. Since 2014, we have developed various complex single- and multiphase solutions there – always in close cooperation with our business partners.

Our insonification technology handles gases from atmospheric pressure to high pressure. The EMAT Flowmeter is suitable for all kind of gases.

While steam flow measurement is especially important in power plants, process heat and steam distribution are also measured in many other industries.

The EMAT Flowmeter provides highly accurate flow measurement of any liquid throughout a wide range of flow rates, viscosities and extreme cold and hot temperatures.

ROSEN is a leading company that was established as a one-man business in 1981. Over more than 40 years, ROSEN has grown rapidly and is today a worldwide technology group that operates in more than 120 countries with over 4,000 employees.

The ROSEN Group is a worldwide provider of cutting-edge solutions in all areas of the integrity process chain suiting a wide range of industries: oil and gas, energy, process, mining, manufacturing, telecommunications and transportation for a wide range of assets, including pipeline, tanks and vessels as well as wind turbines, trains, telecommunication towers and many more.

Please contact us and we will be happy to provide you with more information.